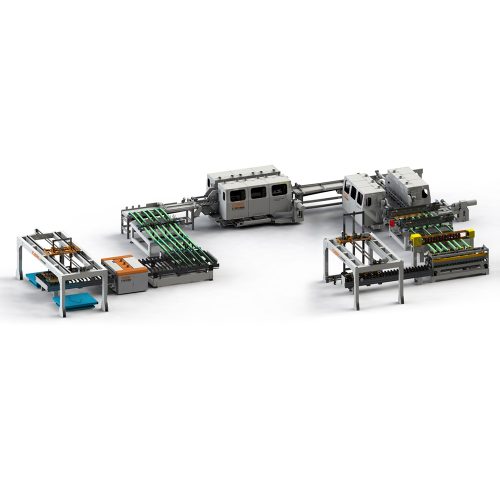

Loading and Unloading Connection Equipment for SPC Profiling Line

- This production line is mainly used for saw cutting and slotting connection, which is composed of gantry loading machine, multi-blade saw, slotting line, flapping machine, dust collector, stacking machine and palletizing machine, which can basically meet the general flooring cutting and profiling process.

- Gantry feeder has board distribution function, this device can effectively separate the flooring, to avoid 2 or more boards pasted together and be attracted to the processing equipment to damage the equipment or damage the flooring.

- This production line is flexible and easy to operate. It is possible to realize all the flooring without the work process offline, greatly reduce handling, reduce labor, and improve work efficiency. One line uses 1 worker (except inspection personnel) to complete the production line operation, and the operator only needs to do material supplement and logistics work. The hard handling work of plate loading and unloading is completed by the equipment.

- The production line can change the corresponding combined configuration according to the actual site and process requirements, such as feeding increase 360 degree cycle flapping machine.

Customized Service for

Each Of Your Flooring Automatic Packaging System

- We Find Key Solutions

We can customize the size of the packaging carton to suit your needs

- Imported sensor systems

We can customize the size of the packaging carton to suit your needs

Do you want to know more about Loading and Unloading Connection Equipment for SPC Profiling Line?

Specifications of the Loading and Unloading Equipment for SPC Profiling Line

| Name | QTY. | Number |

|---|---|---|

| hydraulic lifting table | 2 | 1 |

| uniaxial duplex work station loading manipulator | 1 | 2 |

| positioning conveying roller table | 1 | 3 |

| multiple blade saw | 1 | 4 |

| turn angle conveying roller table | 1 | 5 |

| transition conveying roller table | 1 | 6 |

| plate turnover and conveying machine | 1 | 7 |

| profiling line | 1 | 8 |

| plate turning and dust removal machine | 1 | 9 |

| checking and conveying line | 1 | 10 |

| interval plate turnover machine | 1 | 11 |

| simple conveying line | 1 | 12 |

| stacking machine | 1 | 13 |

| positioning conveying roller table | 1 | 14 |

| unloading and palletizing machine | 1 | 15 |

Components Brand

| Name | Standard Configuration (semi-automatic) | High-level Configuration (semi-automatic) | Standard Configuration (fully automatic) | High-level Configuration (fully automatic) |

|---|---|---|---|---|

| PLC | INOVANCE | MITSUBISHI | BECKHOF | BECKHOF |

| Inverter | INOVANCE | MITSUBISHI | INOVANCE | Schneider |

| Servo Motor | INOVANCE | MITSUBISHI | INOVANCE | Panasonic |

| Touch Screen | MCGS | MITSUBISHI | 21.5 inch | 21.5 inch |

| Reducer / four series Gearbox | Jiacheng | Jiacheng | Jiacheng | Jiacheng |

| Reducer / low power Gearbox | CPG | CPG | CPG | CPG |

| Speed Reducer / Planet Gearbox | ZhognDa | ZhognDa | ZhognDa | ZhognDa |

| Pneumatic Cylinders | AirTAC | AirTAC | AirTAC | AirTAC |

| Photoelectric Switch | Autonics | sick | Autonics | sick |

| Low-voltage Apparatus | Schneider | Schneider | Schneider | Schneider |

| Straight Slide Track | THK | THK | THK | THK |

| Hot Melt Machine | Oshda | Nordson | Oshda | Nordson |

Get in touch

Our expert support team will answer all your questions.