Osike Equipment Catalogue

It’s not easy to introduce all aspects of OSIKE equipment, so we’ve prepared a lot of information on this page for you to delve into. To make sure you can quickly find the information you want, we have prepared this content directory that will jump to the appropriate location when you click on it.

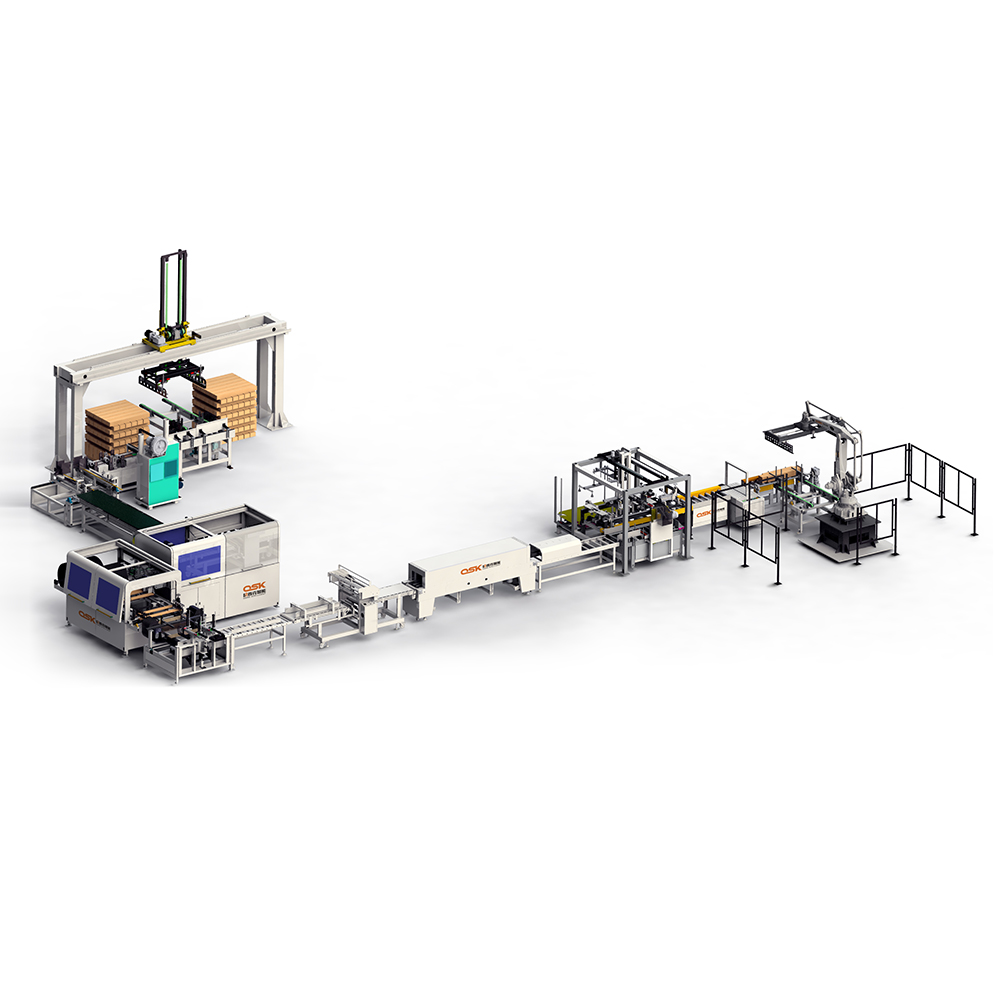

Floor automatic packaging machine

Your products – our inspiration

The perfect solution

Our expertise in packaging equipment is based on more than ten years of experience.

Our equipment can help you to minimize labor and material resources and guarantee product quality.

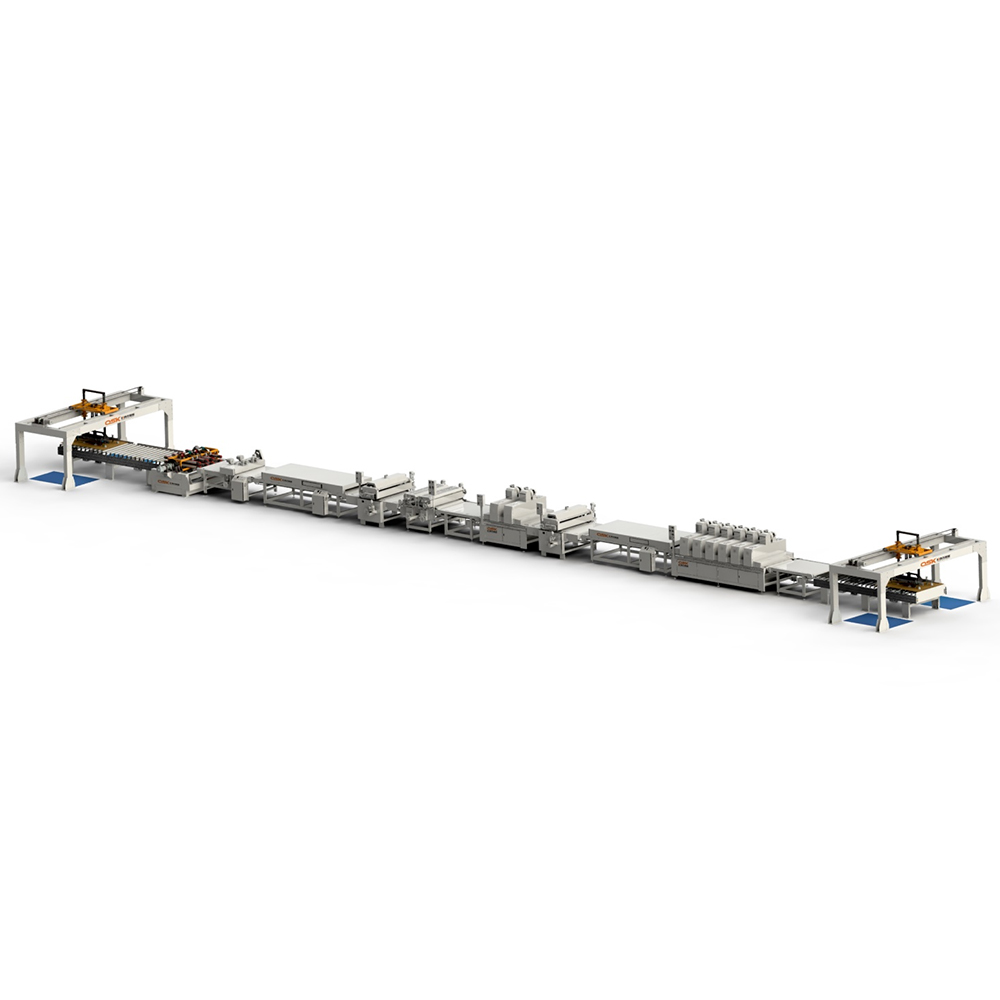

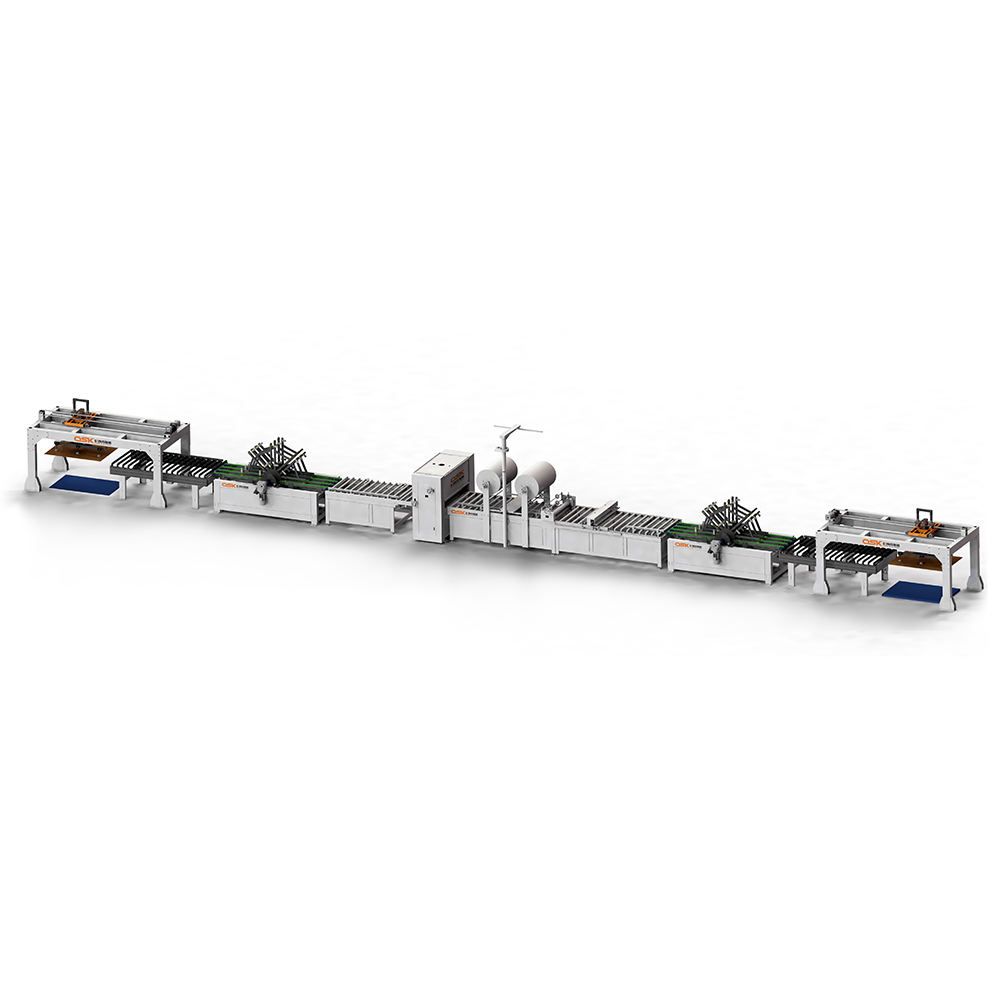

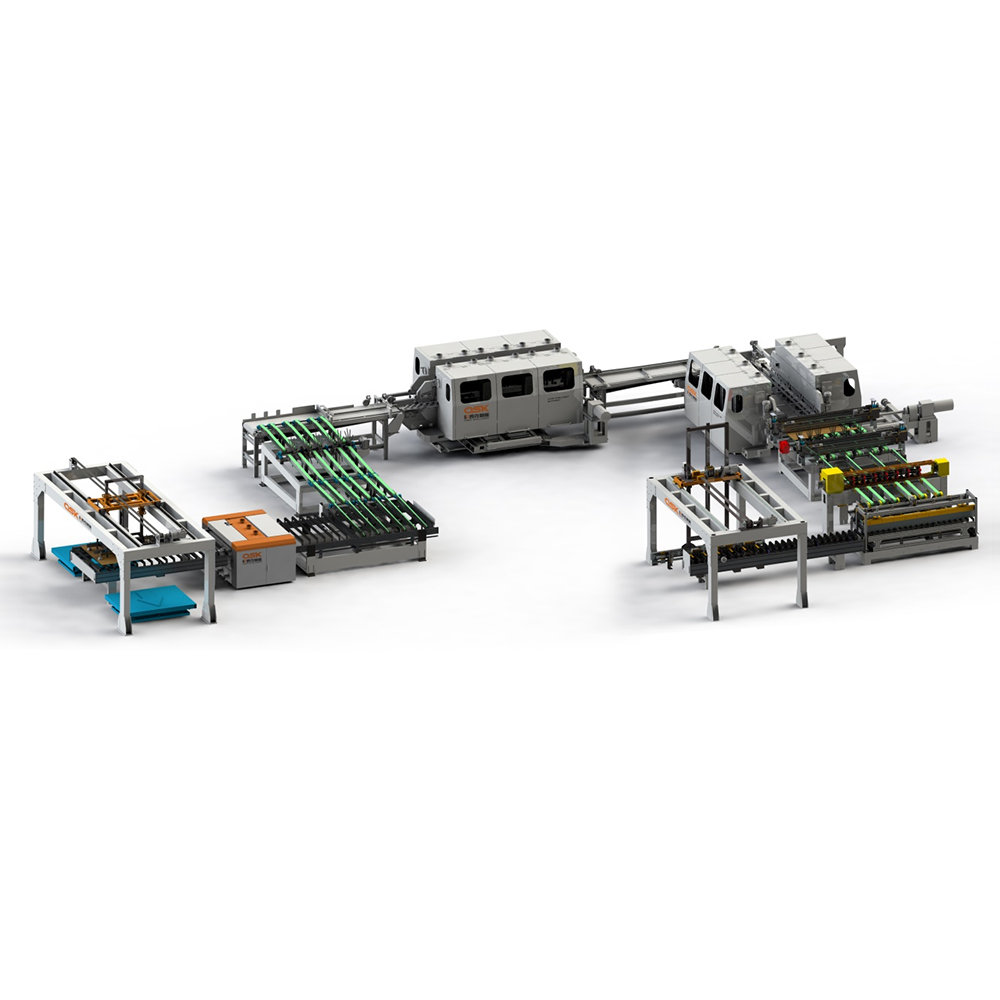

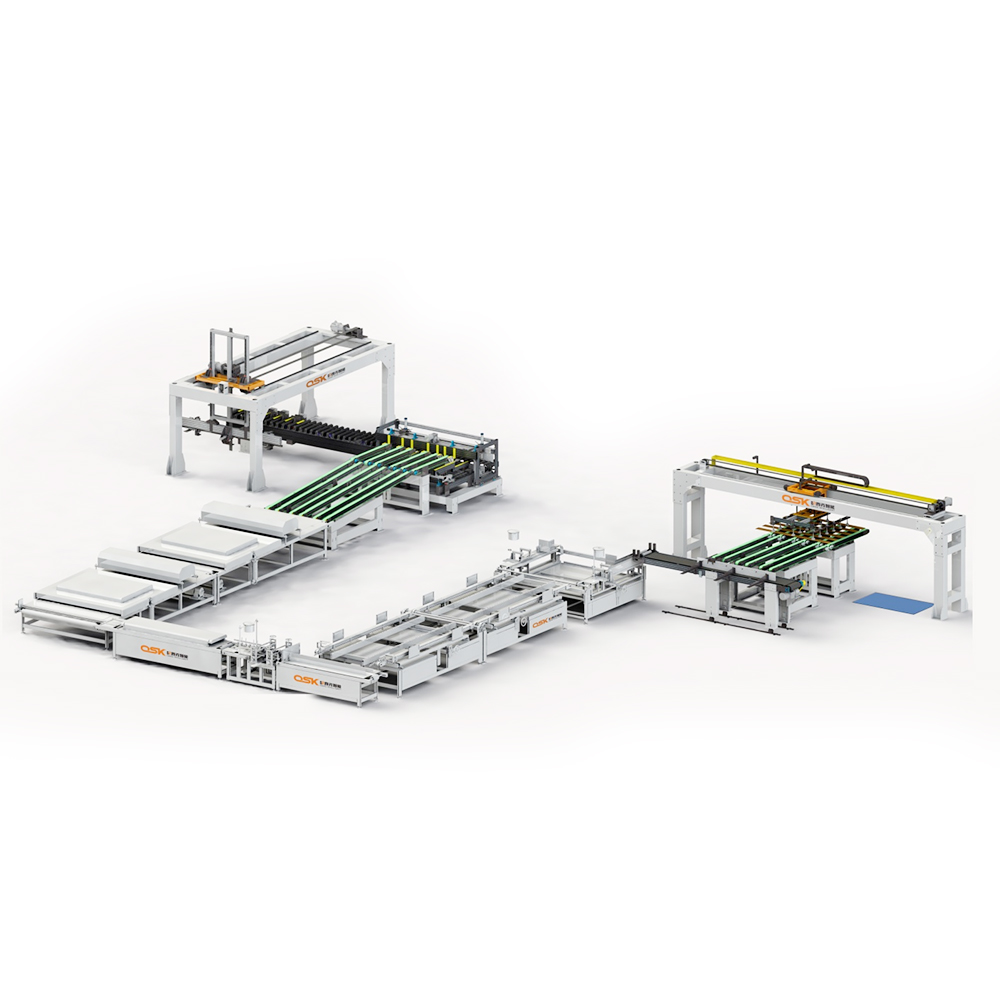

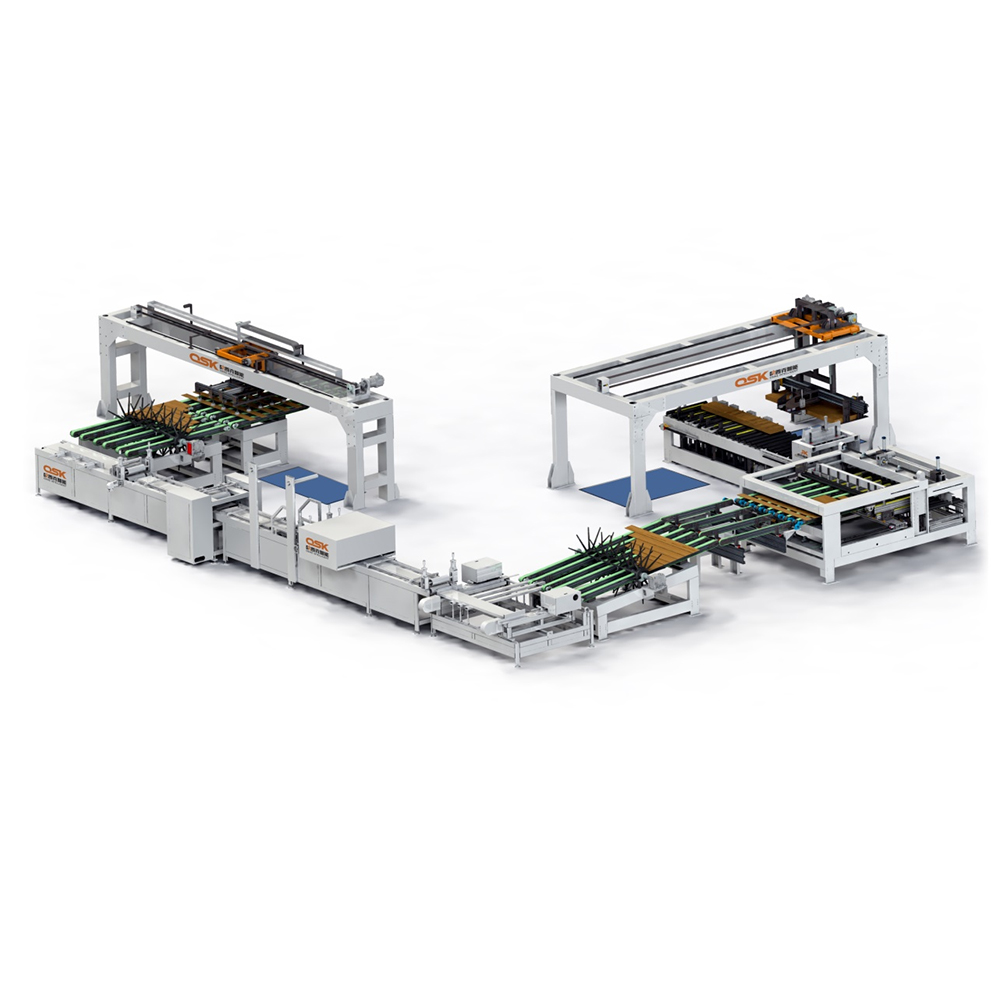

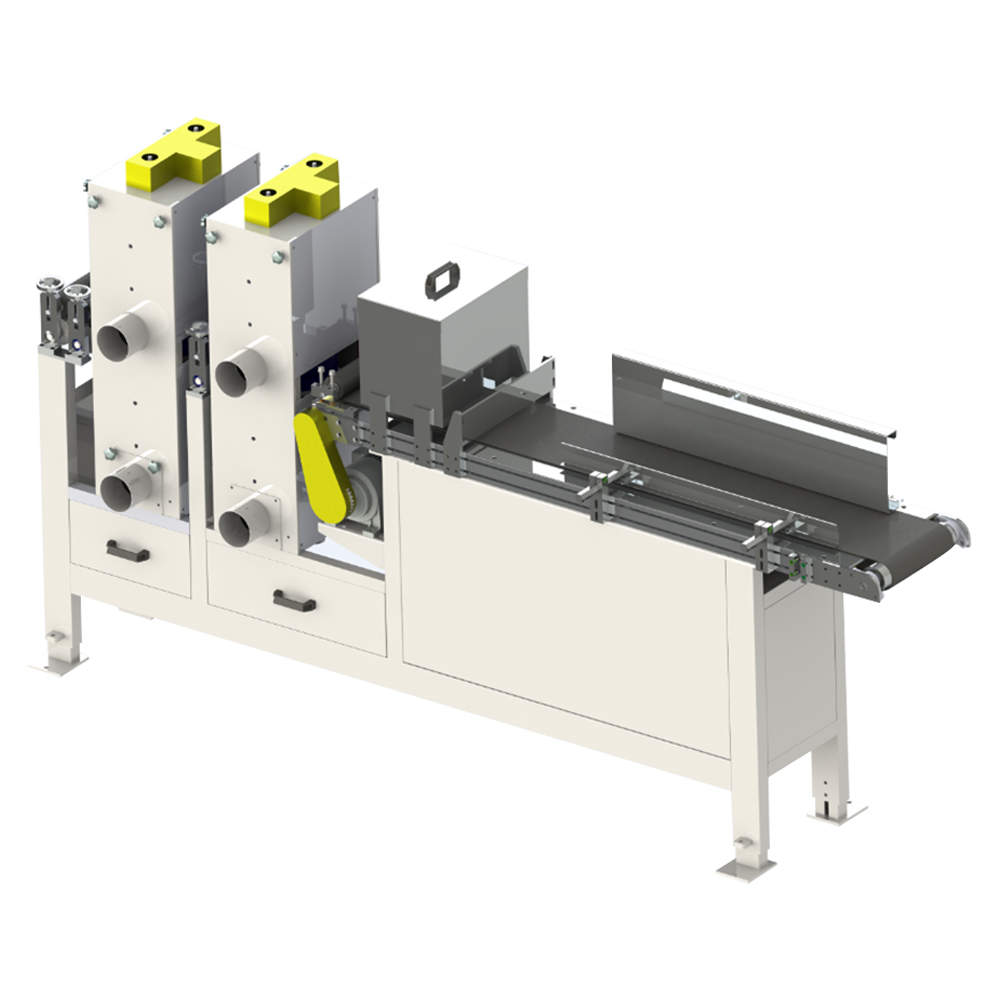

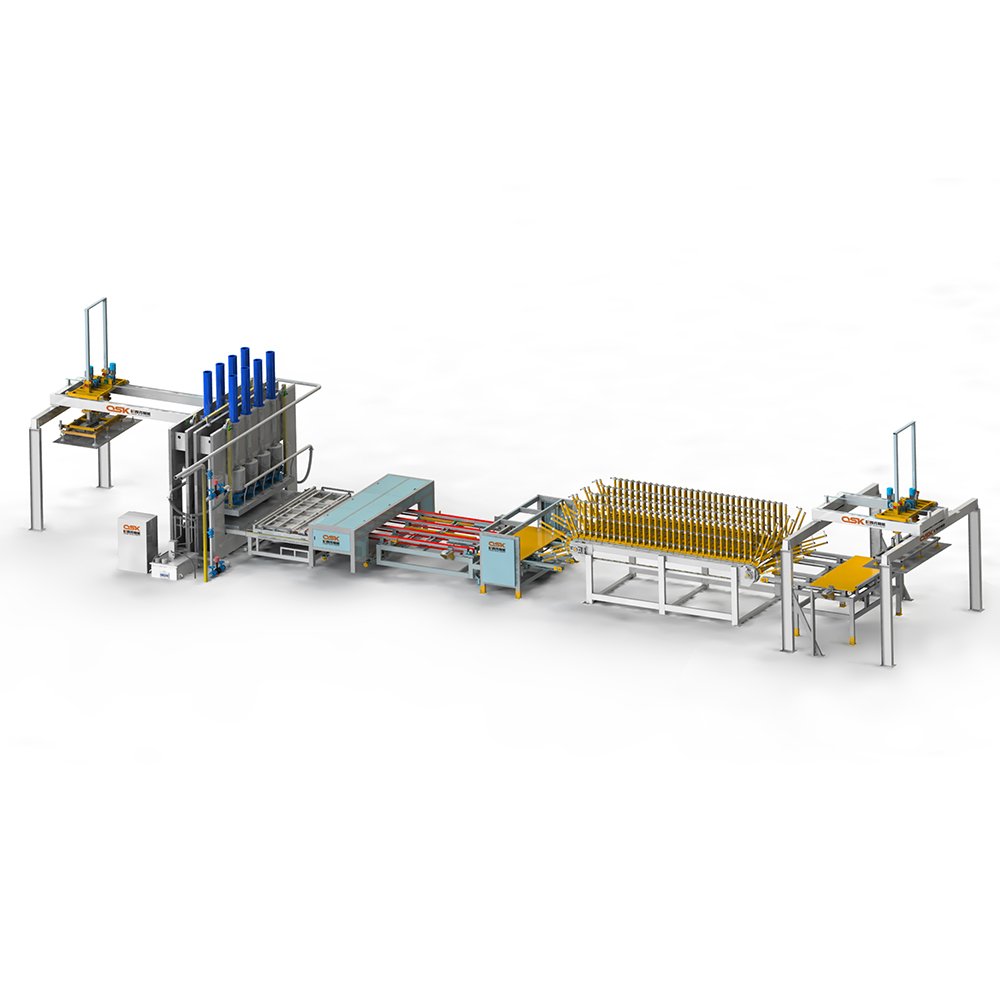

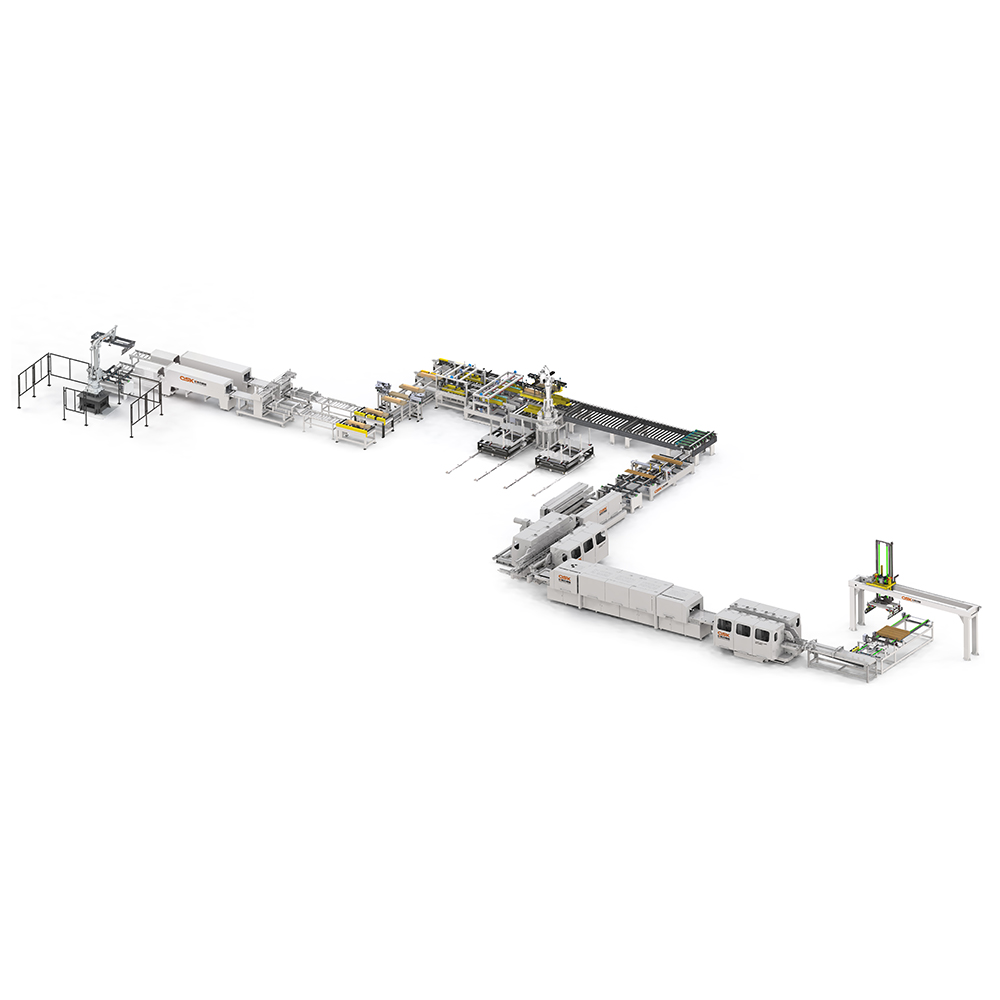

Structure demonstration

Adopting modular design and step-by-step processing packaging method, the automatic packaging operation with orderly division of labor is carried out on one machine.

Product parameters of our equipment

Here are regular products that I have specially prepared for you,welcome to inquire.

In addition, we also support customization, if you have any other requirements, we can help you free design with samples.

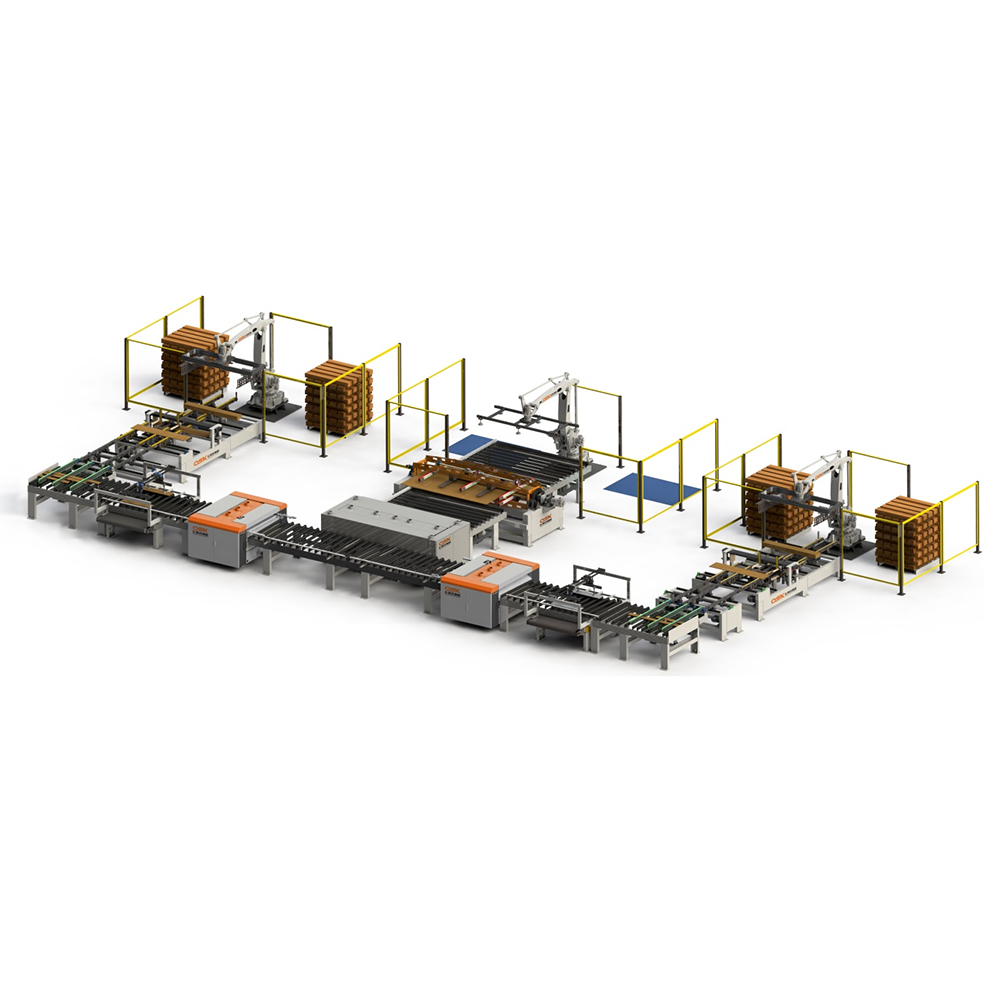

Floor Automatic Packaging Machine

1.PLC program controller: Q series Mitsubishi (Japan)

2. Touch screen: Mitsubishi (Japan)

3. Servo system: Mitsubishi (Japan)

4. Inverter: Mitsubishi (Japan) or Schneider (France)

1. Photoelectric switch: SICK (Germany)

2. Proximity switch: Otto Nix (Korea)

3. Magnetic switch: SMC or Festo

1. Manipulator horizontal walking deceleration mechanism: reducer + Mitsubishi high-speed servo motor

2. Linear motion mechanism, synchronous belt pulley machine, linear guide: THK (Japan) or HWIN on the silver

1. Each detection and protection are used double safety protection measures

2. Contactor, intermediate relay: Schneider (Germany) or AB (U.S.)

3. Drag chain cable: high-speed flexible motion cable (North America UL standard)

1. Cylinder: ADATA, standard customized

2. Solenoid valve: SMC (Japan)

3. Oil-water separator: SMC (Japan)

1. Package length: 900-1860mm

2.Packing width: 125-310mm

3. Packaging thickness: 40-110mm

4. Weight of the shifted plate: ≤60kg

5. Maximum height of palletizing by robot: (including pallet) 1000mm

6. Maximum speed of palletizing: 4 times/minute

7. Palletizing mode: parallel palletizing

8.c Adopt 250×150 thickened rectangular tube, heavy-duty aluminum fixed panel, aviation aluminum profile, accessories using laser processing.

AC480V 60HZ

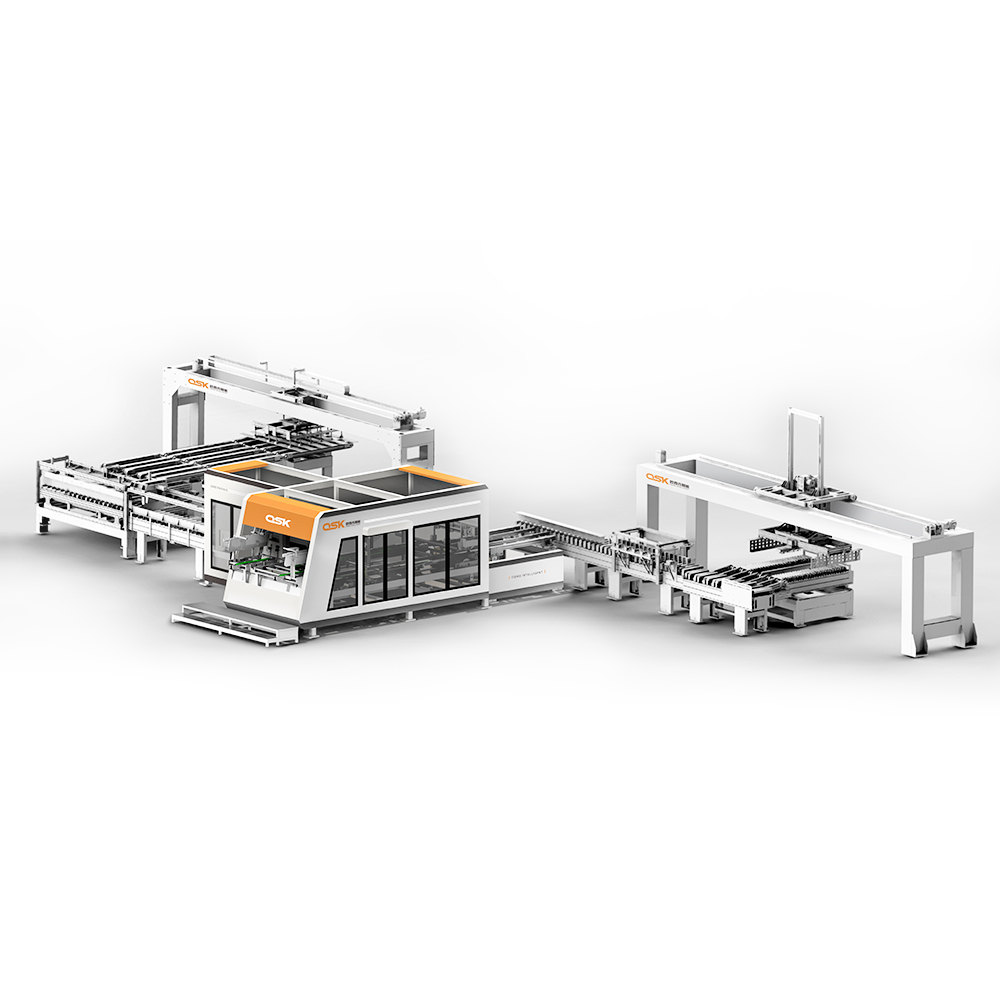

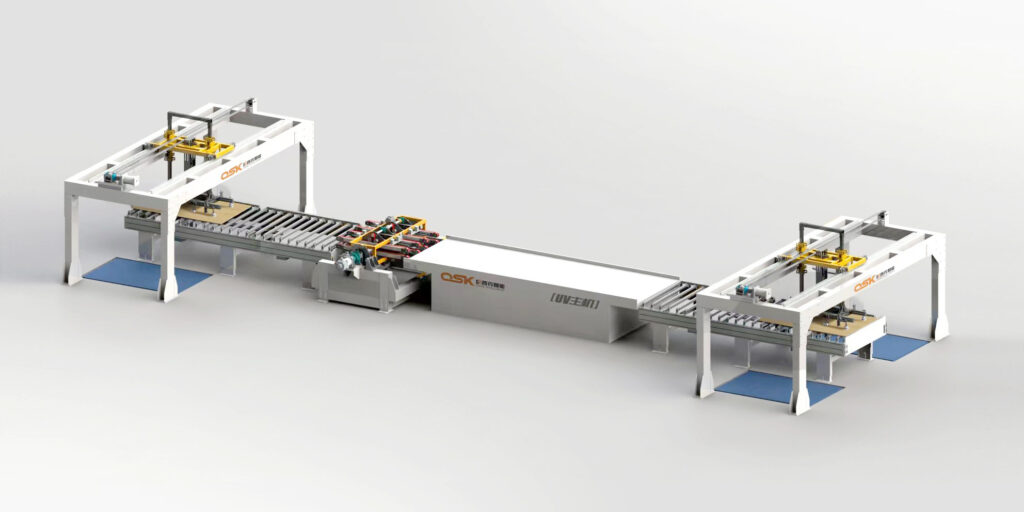

Floor UV Coating Machine

1.PLC program controller: Q series Mitsubishi (Japan)

2. Touch screen: Mitsubishi (Japan)

3. Servo system: Mitsubishi (Japan)

4. Inverter: Mitsubishi (Japan) or Schneider (France)

1. Photoelectric switch: SICK (Germany)

2. Proximity switch: Otto Nix (Korea)

3. Magnetic switch: SMC or Festo

1. Manipulator horizontal walking deceleration mechanism: reducer + Mitsubishi high-speed servo motor

2. Linear motion mechanism, synchronous belt pulley machine, linear guide: THK (Japan) or HWIN on the silver

1. Each detection and protection are used double safety protection measures

2. Contactor, intermediate relay: Schneider (Germany) or AB (U.S.)

3. Drag chain cable: high-speed flexible motion cable (North America UL standard)

1. Cylinder: ADATA, standard customized

2. Solenoid valve: SMC (Japan)

3. Oil-water separator: SMC (Japan)

1. Package length: 900-1860mm

2.Packing width: 125-310mm

3. Packaging thickness: 40-110mm

4. Weight of the shifted plate: ≤60kg

5. Maximum height of palletizing by robot: (including pallet) 1000mm

6. Maximum speed of palletizing: 4 times/minute

7. Palletizing mode: parallel palletizing

8.c Adopt 250×150 thickened rectangular tube, heavy-duty aluminum fixed panel, aviation aluminum profile, accessories using laser processing.

AC480V 60HZ

General Applications For FLOOSIKER Equipment

FLOOSIKER machines are used in a wide range of applications, typically for SPC floorb processing, packaging, etc. With long life and low noise performance, as well as various safety certifications, our products are able to your needs.

Get in touch

Our expert support team will answer all your questions.