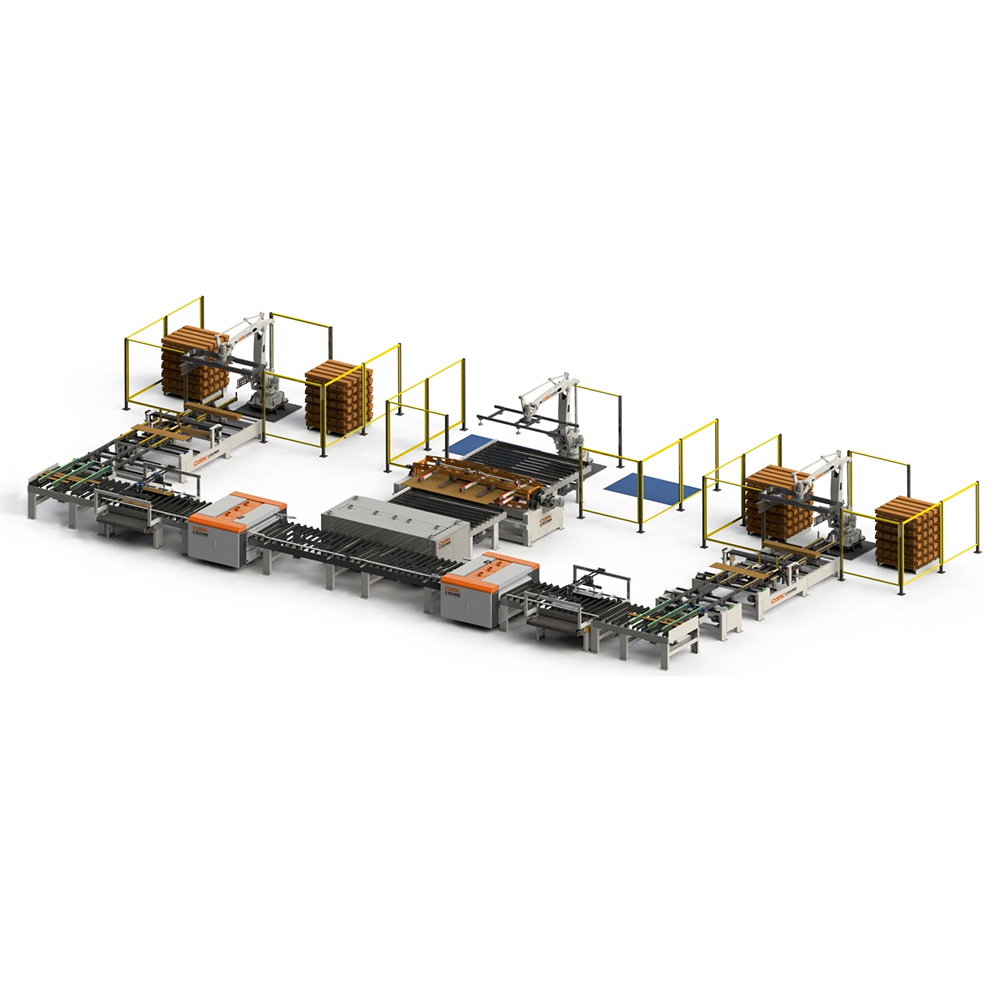

Loading and Unloading Equipment for Laminate Floor Saw Cutting Line

- This production line is mainly used for the laminate floor saw cutting, combination of robot, interval flap machine, three-blade saw, multi-blade saw, edge-trimming machine, stacking machine, etc., Can basically meet the general flooring small piece sawing process.

- The system has advanced technology, safe and reliable, high production efficiency, with automatic feeding, pallet change function; the boards suction is achieved by whole suction plate, low requirements on the boards level, particularly suitable for slitting and post-slitting stacks of slitted and perked boards.

- This production line is flexible and easy to operate. It is possible to realize all the flooring without the work process offline, greatly reduce handling, reduce labor, and improve work efficiency. One line uses 1 worker (except the side board cutting personnel) can complete the production line operation, and the operator only need to do material supplement and logistics work. The hard handling work of plate loading and unloading is completed by the equipment.

Customized Service for

Each Of Your Flooring Automatic Packaging System

- We Find Key Solutions

We can customize the size of the packaging carton to suit your needs

- Imported sensor systems

We can customize the size of the packaging carton to suit your needs

Do you want to know more about High-speed Side Flap Machine?

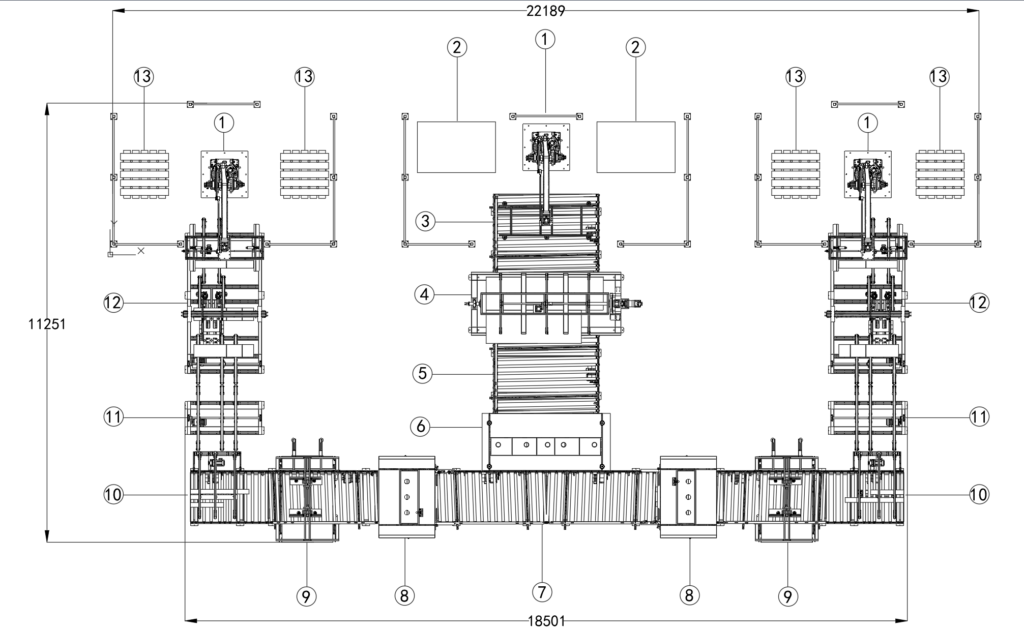

Specifications of the Loading and Unloading Equipment for Laminate Floor Saw Cutting Line

| Name | QTY. | Number |

|---|---|---|

| palletizing robot | 3 | 1 |

| hydraulic lifting table | 2 | 2 |

| loading and conveying table | 1 | 3 |

| 360-degree cycle plate turnover machine | 1 | 4 |

| three-blade saw feeding roller table | 1 | 5 |

| three-blade saw | 1 | 6 |

| feeding and conveying roller table | 1 | 7 |

| multiple blade saw | 2 | 8 |

| edge trimmer | 2 | 9 |

| turn angle conveying roller table | 2 | 10 |

| belt conveyor machine | 2 | 11 |

| intelligent stacking machine | 2 | 12 |

| palletizing working station with pallets | 4 | 13 |

Main Technical Data

| Items | Standard Parameters |

|---|---|

| Working Cycles | ≤10 times per min |

| Large Board Size | ≤ 2440-3050 x 1220 X8-15mm |

| Small Board Size | ≤ 820-1520 x 120-320 X8-15mm |

Components Brand

| Name | Standard Configuration | High-level Configuration |

|---|---|---|

| PLC | INOVANCE | MITSUBISHI |

| Inverter | INOVANCE | MITSUBISHI |

| Servo Motor | INOVANCE | MITSUBISHI |

| Reducer / four series Gearbox | Jiacheng | Jiacheng |

| Reducer / low power Gearbox | CPG | CPG |

| Speed Reducer / Planet Gearbox | ZhognDa | ZhognDa |

| Pneumatic Cylinders | AirTAC | AirTAC |

| Photoelectric Switch | Autonics | sick |

| Low-voltage Apparatus | Schneider | Schneider |