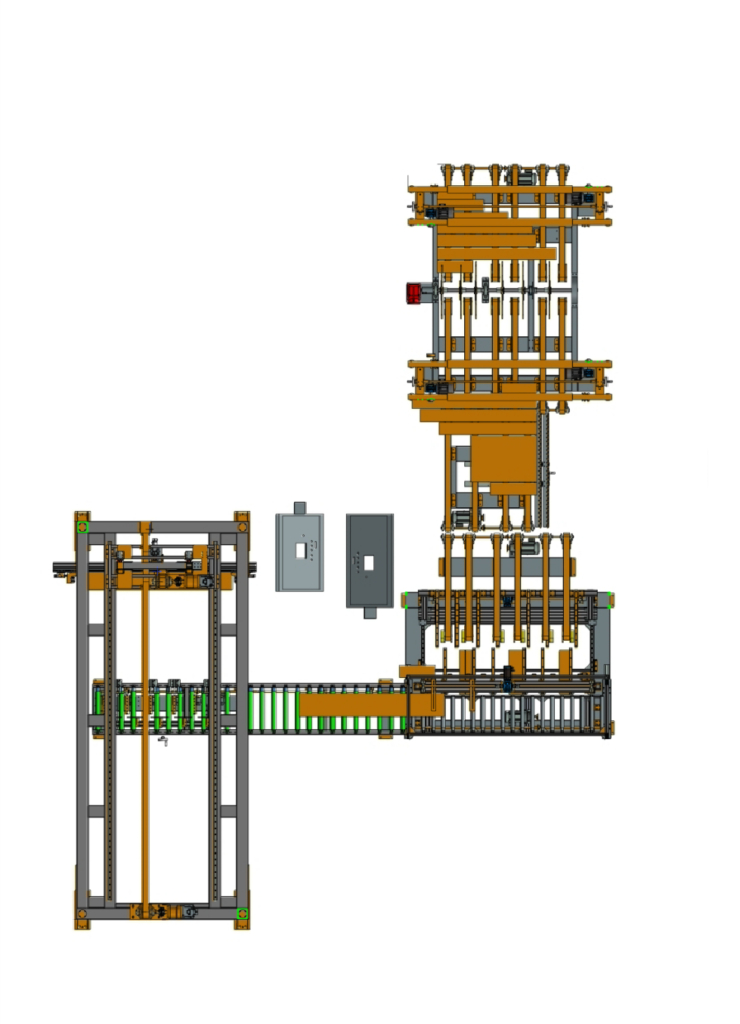

Automatic Packaging Machine System

OSIKE WS-R series high-speed LVT/SPC flooring hot melt wrapping automatic packaging machine independently developed and produced by Osike adopts PLC intelligent module control system, precision sprocket chuck type transfer mechanism, together with European original hot melt glue machine and high precision spray gun, through the intermittent processing station packaging control method, to achieve a wrapping packaging speed of 10 to 12 packages per minute, which can directly match the working speed of 100m/minute slotting machine. At the same time, it is possible to set a variety of packaging sizes on one machine, which is easy to adjust and easy for users to operate.

Packaging Machine Technology Highlights

On each wrapping machine, the sides and top and bottom edges of the cardboard are automatically formed and fixed with hot melt adhesive. The formed packages are then sent out of the machine via a roller conveyor and automatically stacked and folded.

High packing efficiency, 10 to 12 packs per minute;

Wide range of sizes, easy and fast size changeover;

Tightly wrapped, not loose, firmly sealed;

Reliable structure, stable system, low failure rate.

More Advantages

Modularized design of packaging platform will bring fluent packaging operation;

Driving structure adopts mechanical linkage, which will promote the stability and fluency during packaging;

Intelligent PLC control will bring high stability and repeatability of actions;

Friendly touch screen HMI for easier operation;

Intelligent design, quick and easy to adjust a variety of floor packaging specifications;

All the components adopt international top brand, which can ensure the stability and reliability of our machine;

Various safety protection systems such as fault alarm and safety fence.

Customized Service for

Each Of Your Flooring Automatic Packaging System

- We Find Key Solutions

We can customize the size of the packaging carton to suit your needs

- Imported sensor systems

We can customize the size of the packaging carton to suit your needs

Do you want to know more about automatic packaging machine?

The machine included two parts: Automatic Packaging and Automatic Stacking, the processing is :

Operation Theory

The plastic flooring is stacked and positioned, then fed into the machine by a roller conveyor belt, and the plastic flooring cardboard is pushed into the machine via the feeding device. The plastic flooring that is fed into the cardboard is conveyed by pushers and chains. At each packing station, the sides and top and bottom edges of the cardboard are automatically formed and fixed with hot melt adhesive. The formed packages are then transported out of the machine via a roller conveyor for automatic stacking.

Standard Model Technical Data

| Type | Hot Melt Adhesive Type Floor Packaging Machine (semi-automatic) | Hot Melt Adhesive Type Floor Packaging Machine (automatic) |

|---|---|---|

| Rated Capacity | 10-12 packs / minute | 10-12 packs / minute |

| Carton Height | 40~120mm | 40~120mm |

| Carton Width | Carton Width | 120~310mm |

| Carton Length | 900~1860mm | 900~1530mm |

| Carton Storage | More than 250 sheets (paper thickness: 3mm) | More than 250 sheets (paper thickness: 3mm) |

| Mechanical Material | Aluminum profile and rust-proof place in the spray-painted carbon steel | Aluminum profile and rust-proof place in the spray-painted carbon steel |

| Specification Switching Time | Less than 25 minutes | Less than 10 minutes |

| Equipment Color | Industrial grey | Industrial grey |

| Total Power of Equipment | 34.5 kW (including palletizing) | 34.5 kW (including palletizing) |

| Air Supply | 0.6~0.8MPa | 0.6~0.8MPa |

| Gas Consumption | 0.5m³/min | 0.5m³/min |

| Working Voltage | Three phase 380 V, 50 Hz, single phase 220 V, 50 Hz | Three phase 380 V, 50 Hz, single phase 220 V, 50 Hz |

| Control Voltage | 24V and at the DC level | 24V and at the DC level |

Components Brand

| Name | Standard Configuration (semi-automatic) | High-level Configuration (semi-automatic) | Standard Configuration (fully automatic) | High-level Configuration (fully automatic) |

|---|---|---|---|---|

| PLC | INOVANCE | MITSUBISHI | BECKHOF | BECKHOF |

| Inverter | INOVANCE | MITSUBISHI | INOVANCE | Schneider |

| Servo Motor | INOVANCE | MITSUBISHI | INOVANCE | Panasonic |

| Touch Screen | MCGS | MITSUBISHI | 21.5 inch | 21.5 inch |

| Reducer / four series Gearbox | Jiacheng | Jiacheng | Jiacheng | Jiacheng |

| Reducer / low power Gearbox | CPG | CPG | CPG | CPG |

| Speed Reducer / Planet Gearbox | ZhognDa | ZhognDa | ZhognDa | ZhognDa |

| Pneumatic Cylinders | AirTAC | AirTAC | AirTAC | AirTAC |

| Photoelectric Switch | Autonics | sick | Autonics | sick |

| Low-voltage Apparatus | Schneider | Schneider | Schneider | Schneider |

| Straight Slide Track | THK | THK | THK | THK |

| Hot Melt Machine | Oshda | Nordson | Oshda | Nordson |