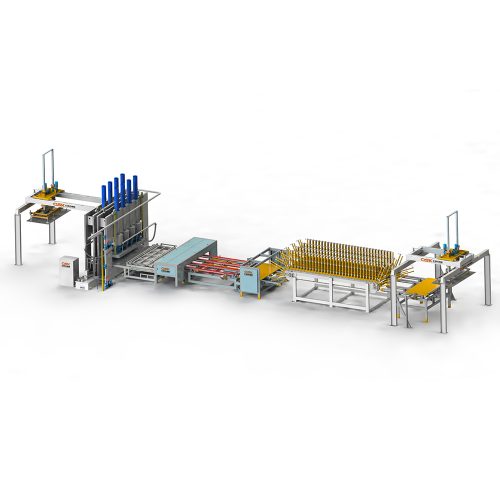

Hot Press Laminating Fast Production Line

- This production line is mainly used for laminate floor, furniture board and other short period hot press veneer, which is composed of truss manipulator loading, incoming plate hot press, outgoing board clear edge, cooling plate, truss manipulator palletizing and so on, which fully meets the production process of short period hot press veneer.

- The equipment with advanced technology, safe and reliable, high production efficiency, feeding automatically with air positioning function, can be pressed and applied without manual labor, automatic switching of different widths for pressing and pasting needs, can be set for plate processing,cleaning,inspection,cooling and palletizing requirements. The machine can add the function equipment such as dust removal of single sheet of plain board, automatic paper laying and sorting, classification of finished and defective products.

- This production line is flexible and easy to operate. Can realize the mechanized operation of all plates, reduce manual handling and improve work efficiency. One production line uses 1 worker to complete the production operations.

Customized Service for

Each Of Your Flooring Automatic Packaging System

- We Find Key Solutions

We can customize the size of the packaging carton to suit your needs

- Imported sensor systems

We can customize the size of the packaging carton to suit your needs

Do you want to know more about Hot Press Laminating Fast Production Line?

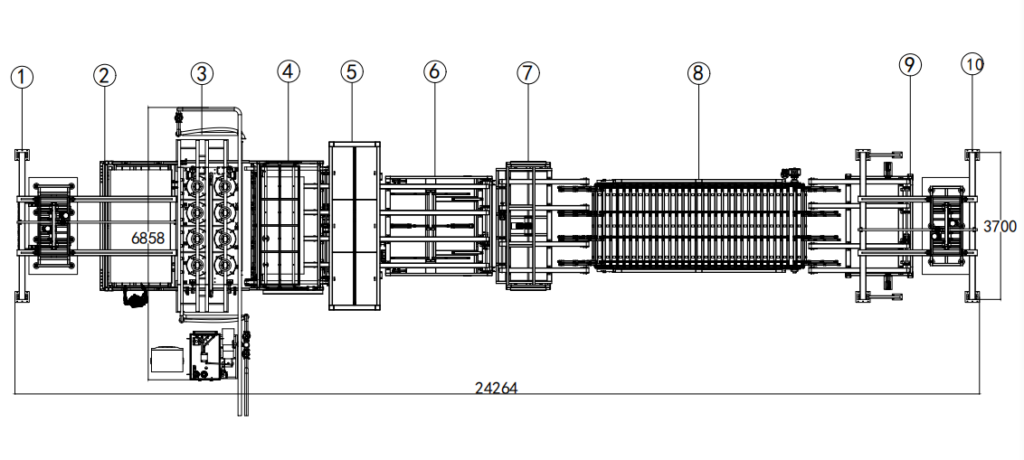

Hot Press Laminating Fast Production Line

| Name | QTY. | Number |

|---|---|---|

| truss manipulator loading | 1 | 1 |

| plate in trolley | 1 | 2 |

| hot press machine | 1 | 3 |

| plate out trolley | 1 | 4 |

| edge cleaning and dust removal machine | 1 | 5 |

| plate turnover and conveying machine | 1 | 6 |

| lift transition conveyor | 1 | 7 |

| board drying table | 1 | 8 |

| positioning conveyor | 1 | 9 |

| truss manipulator palletizing | 1 | 10 |

Main Technical Data

| Items | Standard Parameters |

|---|---|

| Working Cycles | ≤ 2-3 sheets / minute |

| Large Board Size | ≤ 3050 x 2745 X8-30mm |

| Small Board Size | ≤ 1830-2800 x 1220-1300 X8-30mm |

Components Brand

| Components | Standard Configuration | High-level Configuration |

|---|---|---|

| PLC | INOVANCE | MITSUBISHI |

| Inverter | INOVANCE | MITSUBISHI |

| Servo Motor | INOVANCE | MITSUBISHI |

| Reducer / four series Gearbox | Jiacheng | Jiacheng |

| Reducer / low power Gearbox | CPG | CPG |

| Speed Reducer / Planet Gearbox | ZhognDa | ZhognDa |

| Pneumatic Cylinders | AirTAC | AirTAC |

| Photoelectric Switch | Autonics | sick |

| Low-voltage Apparatus | Schneider | Schneider |