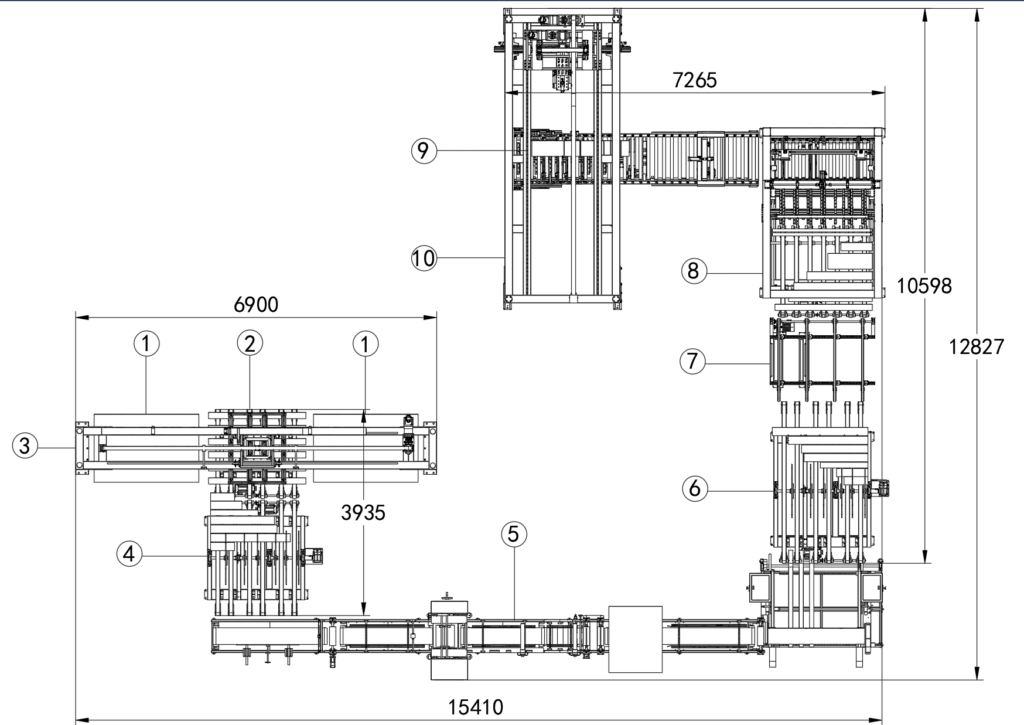

Loading and Unloading Connection Equipment for Small Plate Padding Line

- This production line is mainly used for the connection of small plate padding line, which is composed of gantry loading machine, plate turnover machine, small plate padding machine, stacking machine and palletizing machine, which can basically meet the small plate padding process of general flooring.

- Gantry loading machine can use a suction cup or suction bar to grab the plate.

- This production line is flexible and easy to operate. It is possible to realize all the flooring without the work process offline, greatly reduce handling, reduce labor, and improve work efficiency. One line uses 1 worker (except inspection personnel) to complete the production line operation, and the operator only needs to do material supplement and logistics work. The hard handling work of plate loading and unloading is completed by the equipment.

Customized Service for

Each Of Your Flooring Automatic Packaging System

- We Find Key Solutions

We can customize the size of the packaging carton to suit your needs

- Imported sensor systems

We can customize the size of the packaging carton to suit your needs

Do you want to know more about Loading and Unloading Connection Equipment for Small Plate Padding Line?

Standard Model Technical Data

| Type | Hot Melt Adhesive Type Floor Packaging Machine (semi-automatic) | Hot Melt Adhesive Type Floor Packaging Machine (automatic) |

|---|---|---|

| Rated Capacity | 10-12 packs / minute | 10-12 packs / minute |

| Carton Height | 40~120mm | 40~120mm |

| Carton Width | Carton Width | 120~310mm |

| Carton Length | 900~1860mm | 900~1530mm |

| Carton Storage | More than 250 sheets (paper thickness: 3mm) | More than 250 sheets (paper thickness: 3mm) |

| Mechanical Material | Aluminum profile and rust-proof place in the spray-painted carbon steel | Aluminum profile and rust-proof place in the spray-painted carbon steel |

| Specification Switching Time | Less than 25 minutes | Less than 10 minutes |

| Equipment Color | Industrial grey | Industrial grey |

| Total Power of Equipment | 34.5 kW (including palletizing) | 34.5 kW (including palletizing) |

| Air Supply | 0.6~0.8MPa | 0.6~0.8MPa |

| Gas Consumption | 0.5m³/min | 0.5m³/min |

| Working Voltage | Three phase 380 V, 50 Hz, single phase 220 V, 50 Hz | Three phase 380 V, 50 Hz, single phase 220 V, 50 Hz |

| Control Voltage | 24V and at the DC level | 24V and at the DC level |

Components Brand

| Name | Standard Configuration (semi-automatic) | High-level Configuration (semi-automatic) | Standard Configuration (fully automatic) | High-level Configuration (fully automatic) |

|---|---|---|---|---|

| PLC | INOVANCE | MITSUBISHI | BECKHOF | BECKHOF |

| Inverter | INOVANCE | MITSUBISHI | INOVANCE | Schneider |

| Servo Motor | INOVANCE | MITSUBISHI | INOVANCE | Panasonic |

| Touch Screen | MCGS | MITSUBISHI | 21.5 inch | 21.5 inch |

| Reducer / four series Gearbox | Jiacheng | Jiacheng | Jiacheng | Jiacheng |

| Reducer / low power Gearbox | CPG | CPG | CPG | CPG |

| Speed Reducer / Planet Gearbox | ZhognDa | ZhognDa | ZhognDa | ZhognDa |

| Pneumatic Cylinders | AirTAC | AirTAC | AirTAC | AirTAC |

| Photoelectric Switch | Autonics | sick | Autonics | sick |

| Low-voltage Apparatus | Schneider | Schneider | Schneider | Schneider |

| Straight Slide Track | THK | THK | THK | THK |

| Hot Melt Machine | Oshda | Nordson | Oshda | Nordson |

Get in touch

Our expert support team will answer all your questions.