Unloading Equipment for Extrusion Line

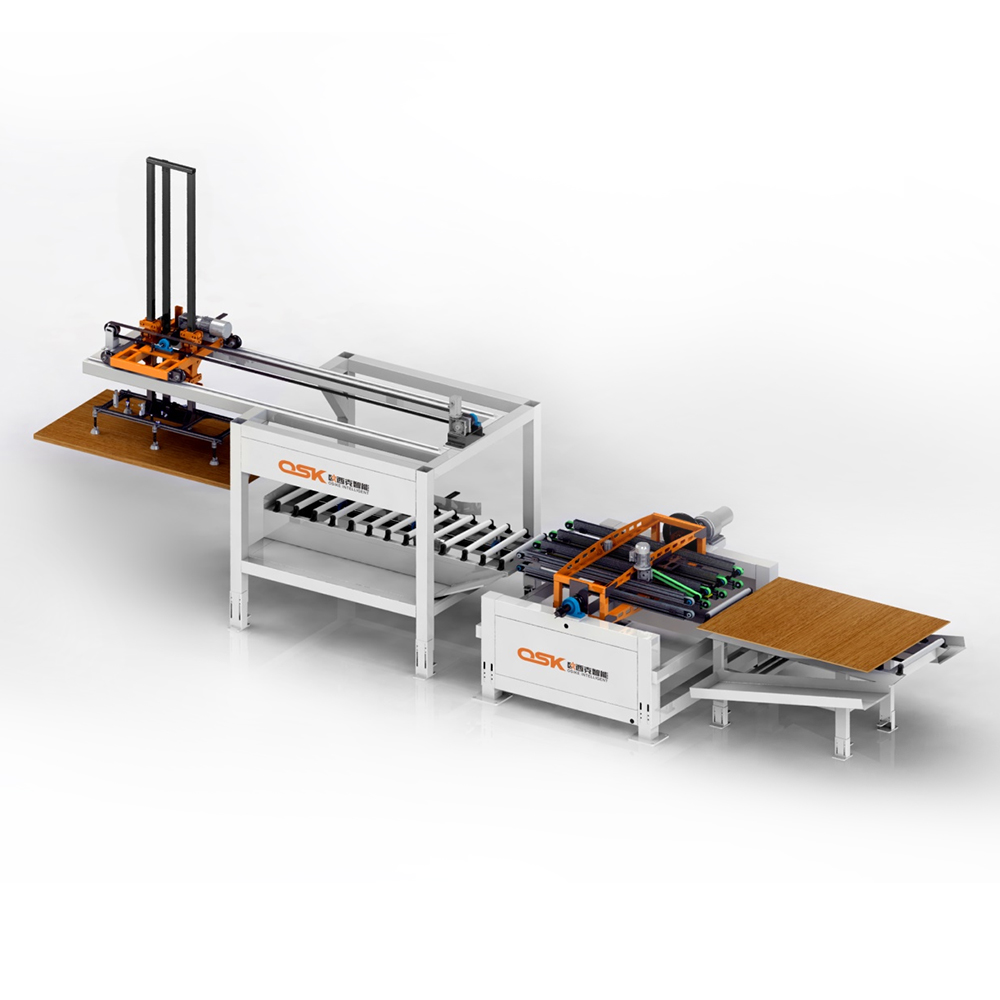

Osike extrusion unloading machine, the main body uses rectangular pipe welding, the structure is solid and stable. The robot horizontal walking and using servo motor with synchronous belt, positioning accurate and fast. The upper and lower lifting mechanism adopts the design of lifting belt, the whole machine adopts mechanical and electrical dual safety system to ensure the safety of the equipment, and adopts PLC intelligent control system, human-machine interface of touch screen is friendly for use. By using the fork shape spaced flap machine or 360 degree cycle plate turnover machine can achieve plate forward and reverse stacking. The unloading machine mainly grasps and moves the boards through sucking the boards surface by vacuum suction cup. Osike unloading machine is an essential supporting equipment for the extruder of the floor and plate furniture manufacturers.

Customized Service for

Each Of Your Unloading Equipment for Extrusion Line

- We Find Key Solutions

We can customize the size of the packaging carton to suit your needs

- Imported sensor systems

We can customize the size of the packaging carton to suit your needs

Do you want to know more about Unloading Equipment for Extrusion Line?

Specifications of the Unloading Equipment for Extrusion Line

| Name | QTY. | Number |

|---|---|---|

| transition conveying roller table | 1 | 1 |

| 360-degree cycle plate turnover machine | 1 | 2 |

| unloading machine | 1 | 3 |

Main Technical Data

| Items | Standard Parameters | High-speed Parameters |

|---|---|---|

| Working Cycles | ≤4 times per min | ≤6 times per min |

| Working Range | ≤900-1860 x 900-1350 X3-10mm | ≤900-1860 x 900-1350 X3-10mm |

| Lifting Range | ≤ 50 KGS | ≤ 50 KGS |

Get in touch

Our expert support team will answer all your questions.