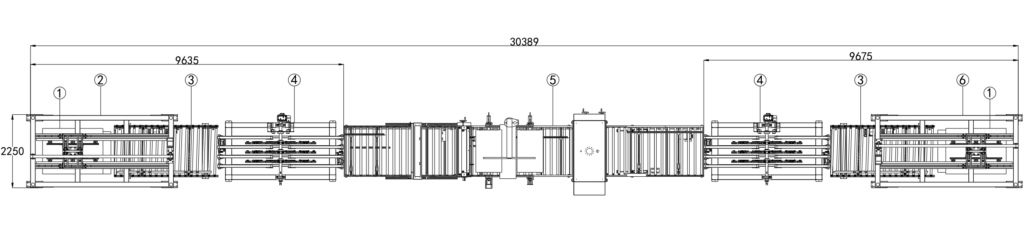

Whole Loading and Unloading Equipment for Large Boards Padding Line

- This production line is mainly used for large board padding by 2 frame gantry machine + 2 typhoon model plate turnover machine + 2 positioning conveying roller table + large board padding machine.

- Gantry feeder has boards distribution function, this device can effectively separate the flooring boards, to avoid 2 or more boards pasted together and be attracted to the processing equipment to damage the equipment or damage the flooring boards.

- This production line is flexible and easy to operate. Can realize all the material loading and unloading, turning plate, positioning and other work. Greatly reduce handling, reduce labor, improve work efficiency. One line uses 1 worker to complete the production line operation, and the operator only needs to supplement the materials. The hard handling work of plate loading and unloading is completed by the equipment.

The windmill flip machine is divided into 8 equal flip plates, flexible and fast flip plates, the frame adopts rectangular square pipe welding, the conveying mechanism adopts straw belt conveying, the flip wheel uses 50 * 50 aluminum profile splicing to reduce the load, the cylinder head and shaft disc side use polyurethane soft glue, to prevent plate damage. When the plate enters the equipment, the belt stops turning or lifting the wheel and in the same time the cylinder press the plate, turn to the set position, release the cylinder pressure at the end of the place where the plate come out, and then the belt starts the output.

Customized Service for

Each Of Your Flooring Automatic Packaging System

- We Find Key Solutions

We can customize the size of the packaging carton to suit your needs

- Imported sensor systems

We can customize the size of the packaging carton to suit your needs

Do you want to know more about Whole Loading and Unloading Equipment for Large Boards Padding Line?

Specifications of the Loading and Unloading Equipment for Large Boards Padding

| Name | QTY. | Number |

|---|---|---|

| hydraulic lifting table | 2 | 1 |

| uniaxial duplex work station loading manipulator | 1 | 2 |

| positioning conveying roller table | 2 | 3 |

| windmill model plate turnover machine | 2 | 4 |

| large board padding machine | 1 | 5 |

| unloading and palletizing manipulator | 1 | 6 |

Main Technical Data

| Items | Standard Parameters | High-speed Parameters |

|---|---|---|

| Working Cycles | ≤ 15 per min | ≤ 22 per min |

| Working Range | ≤ 900-1860 x 900-1350 X3-10mm | ≤ 900-1860 x 900-1350 X3-10mm |

| Lifting Range | ≤ 50 KGS | ≤ 50 KGS |

Components Brand

| Components | Standard Configuration | High-level Configuration |

|---|---|---|

| PLC | INOVANCE | MITSUBISHI |

| Inverter | INOVANCE | MITSUBISHI |

| Servo Motor | INOVANCE | MITSUBISHI |

| Reducer / four series Gearbox | Jiacheng | Jiacheng |

| Reducer / low power Gearbox | CPG | CPG |

| Speed Reducer / Planet Gearbox | ZhognDa | ZhognDa |

| Pneumatic Cylinders | AirTAC | AirTAC |

| Photoelectric Switch | Autonics | sick |

| Low-voltage Apparatus | Schneider | Schneider |

Get in touch

Our expert support team will answer all your questions.